- Business cooperation 400-000-0000

- Customer service center 400-111-0000

- address No. 2, South Section of Science and Technology City Avenue, Gaoxin District, Mianyang City, Sichuan Province

New magnetic materials and device products

Injection molding magnet

Injection molded magnet (referred to as plastic magnet) is a bonded magnet produced by injection molding after mixing and granulating thermoplastic resin and magnetic powder.

According to the requirements of magnetic properties of injection molded magnets and the different use environment, different combinations of resins and magnetic powders can be selected to meet the use requirements.

Due to the injection molding process of the injection molding magnet, the product can be designed into a more complex shape, but also can be directly injection combined with other parts to form a component. The process is reliable, simple and high dimensional precision.

Compared with commonly used sintered magnets (such as sintered rare earth permanent magnet and sintered ferrite), injection molded magnets have better toughness and are not easy to crack under impact load.

Due to its high cost performance, injection molded magnets are widely used in household appliances, automobiles, office equipment, 3C products and other fields.

Learn more

According to the requirements of magnetic properties of injection molded magnets and the different use environment, different combinations of resins and magnetic powders can be selected to meet the use requirements.

Due to the injection molding process of the injection molding magnet, the product can be designed into a more complex shape, but also can be directly injection combined with other parts to form a component. The process is reliable, simple and high dimensional precision.

Compared with commonly used sintered magnets (such as sintered rare earth permanent magnet and sintered ferrite), injection molded magnets have better toughness and are not easy to crack under impact load.

Due to its high cost performance, injection molded magnets are widely used in household appliances, automobiles, office equipment, 3C products and other fields.

New magnetic materials and device products

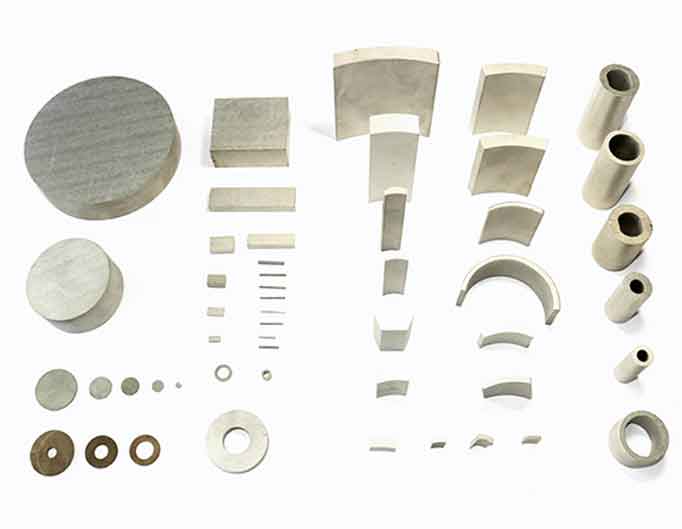

Samarium cobalt magnet

Samarium cobalt magnets Samarium cobalt magnets have the following characteristics:

1, high magnetic properties (high remanence, high coercivity, high magnetic energy product), samarium cobalt magnet at room temperature magnetic capacity of 35MGOe, only lower than NdFeb magnet, far higher than other magnets.

2. The maximum operating temperature is 550℃, which is the highest among all the magnets.

3, with strong corrosion resistance and oxidation resistance, no need for surface corrosion resistance treatment, the magnet can be used for a long time.

4, very low temperature coefficient, generally -0.030%/K.

Widely used in aerospace, national defense, microwave devices, communications, medical instruments, automobiles, magnetic pumps, instruments, various sensors, high-end motor and other industries.

Learn more

1, high magnetic properties (high remanence, high coercivity, high magnetic energy product), samarium cobalt magnet at room temperature magnetic capacity of 35MGOe, only lower than NdFeb magnet, far higher than other magnets.

2. The maximum operating temperature is 550℃, which is the highest among all the magnets.

3, with strong corrosion resistance and oxidation resistance, no need for surface corrosion resistance treatment, the magnet can be used for a long time.

4, very low temperature coefficient, generally -0.030%/K.

Widely used in aerospace, national defense, microwave devices, communications, medical instruments, automobiles, magnetic pumps, instruments, various sensors, high-end motor and other industries.

New magnetic materials and device products

Bonded magnet

Bonded ndFeb magnets are mainly made of ndFeb alloy powder mixed with epoxy resin and pressed, which has the following characteristics:

1, high magnetic properties: magnetic properties between sintered NdFeb magnets and ferrite magnets, consistency and stability is better.

2, high dimensional accuracy, shape freedom: product shape and size by the mold guarantee, can be directly formed for ring, tile, block shape and other free shape, do not need sintering and mechanical processing.

3, good corrosion resistance: after electrophoretic coating or some special treatment, can be used in daily or harsh environment for a long time.

4, flexible and diverse magnetization: magnetic pole can be filled into multi-pole, oblique pole and radial, magnetization surface can be inner circle, outer circle, end face and composite magnetization, waveform can be square wave, sine wave.

Bonded NdFeb magnets are mainly used in all kinds of micro motors, such as spindle motor, stepper motor, synchronous motor, DC motor, brushless DC motor, is also widely used in all kinds of sensor parts. It can partially replace the sintered NdFeb magnet and ferrite magnet, so that the assembly process of the motor is more simple, reliable, lower cost and higher efficiency.

Learn more

1, high magnetic properties: magnetic properties between sintered NdFeb magnets and ferrite magnets, consistency and stability is better.

2, high dimensional accuracy, shape freedom: product shape and size by the mold guarantee, can be directly formed for ring, tile, block shape and other free shape, do not need sintering and mechanical processing.

3, good corrosion resistance: after electrophoretic coating or some special treatment, can be used in daily or harsh environment for a long time.

4, flexible and diverse magnetization: magnetic pole can be filled into multi-pole, oblique pole and radial, magnetization surface can be inner circle, outer circle, end face and composite magnetization, waveform can be square wave, sine wave.

Bonded NdFeb magnets are mainly used in all kinds of micro motors, such as spindle motor, stepper motor, synchronous motor, DC motor, brushless DC motor, is also widely used in all kinds of sensor parts. It can partially replace the sintered NdFeb magnet and ferrite magnet, so that the assembly process of the motor is more simple, reliable, lower cost and higher efficiency.

New magnetic materials and device products

Hot press magnet

The company has two types of hot pressed NdFeb magnets: hot pressed isotropic NdFeb magnets (GHMⅡ) and hot extruding anisotropic NdFeb magnets (GHMⅢ).

Hot pressed isotropic NdFeb magnet (GHMⅡ) is an isotropic magnet obtained by compacting fast-quenched NdFeb magnetic powder at high temperature.

Hot extruded anisotropic NdFeb magnets (GHMⅢ) are mainly anisotropic radiation-oriented ring magnets, which are obtained by using fast quenched NdFeb magnetic powder after compaction and extrusion deformation at high temperature.

Its characteristics are:

1, high magnetic performance, magnetic ring radial maximum magnetic energy product 240 ~ 390kJ/m3.

2, the magnetic ring along the radial orientation, and the radial magnetic can be uniform, can make the motor quiet operation, torque output smooth.

3, high heat resistance, the use temperature can reach 200℃.

4, the number of magnetic pole and magnetic pole helix Angle of the magnetic ring do not need to be predetermined in the forming process, only change the magnetizing coil can be realized, customers use large freedom.

5. The magnetization waveform of the magnetic ring can be magnetized as square wave or other special magnetization waveform according to user requirements.

6, magnetic ring without assembly can achieve multi-pole and pole helix Angle, convenient motor assembly.

7, the magnetic ring is nanocrystalline structure, and high density, using epoxy resin electrophoretic coating, excellent corrosion resistance.

8, magnetic ring is mainly used in a variety of automobile motor, servo motor, electric tool motor and other types of brushless motor.

Learn more

Hot pressed isotropic NdFeb magnet (GHMⅡ) is an isotropic magnet obtained by compacting fast-quenched NdFeb magnetic powder at high temperature.

Hot extruded anisotropic NdFeb magnets (GHMⅢ) are mainly anisotropic radiation-oriented ring magnets, which are obtained by using fast quenched NdFeb magnetic powder after compaction and extrusion deformation at high temperature.

Its characteristics are:

1, high magnetic performance, magnetic ring radial maximum magnetic energy product 240 ~ 390kJ/m3.

2, the magnetic ring along the radial orientation, and the radial magnetic can be uniform, can make the motor quiet operation, torque output smooth.

3, high heat resistance, the use temperature can reach 200℃.

4, the number of magnetic pole and magnetic pole helix Angle of the magnetic ring do not need to be predetermined in the forming process, only change the magnetizing coil can be realized, customers use large freedom.

5. The magnetization waveform of the magnetic ring can be magnetized as square wave or other special magnetization waveform according to user requirements.

6, magnetic ring without assembly can achieve multi-pole and pole helix Angle, convenient motor assembly.

7, the magnetic ring is nanocrystalline structure, and high density, using epoxy resin electrophoretic coating, excellent corrosion resistance.

8, magnetic ring is mainly used in a variety of automobile motor, servo motor, electric tool motor and other types of brushless motor.